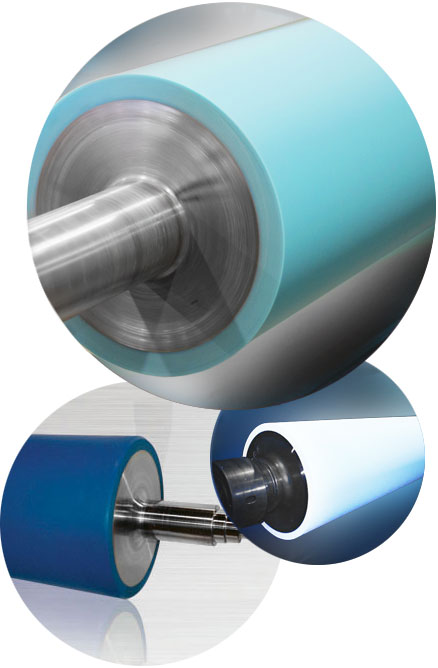

Each of our printing roll covers possess unique properties that determine performance and durability in all critical printing applications.

Clarke leads in the development of advanced new polyurethane polymer and rubber compounds, yet in most printing press applications the use of our specialized rubber coverings continues to expand.

Rubber coverings are most often used for laser engraved plates, laser engraved cylinders and fountain rollers. Every Clarke rubber compound possesses unique properties that determines its performance and durability in all critical printing applications.

Sheetfed Offset Rollers

Our rollers meet all OEM specifications for core weights, hardness and wall thickness, ensuring a precise and even transfer of ink and fountain solutions with minimal adjustments.

Web & Newspaper Offset Rollers

The need to increase productivity, reduce waste and maintain high quality print results means ever higher press speeds and wider sheet widths. Roller compounds must withstand the rigours of this punishing operating environment.

Because we understand the operating environment so thoroughly our coverings have consistently improved roll performance and reduced down time for our printing customers. At Clarke we are continuously refining our products and services to meet the challenges facing the printing industry – we can help you to improve your overall operating performance.

485 Southgate Drive

Guelph, Ontario N1G 3W6, Canada

Phone

519-763-7655

Fax

519-763-7699

Email

485 Southgate Drive

Guelph, Ontario N1G 3W6, Canada

Phone

519-763-7655

Fax

519-763-7699

Email